Metrios advanced, non-contact measurement systems offer a comprehensive inspection solution for a wide range of applications across a variety of industries including aerospace, medical and manufacturing.

Ranging from mass-produced parts to intricate metal components and sensitive materials, Metrios’ advanced measurement capabilities provides a valuable inspection solution for a diverse range of measurement needs.

Explore some of the key applications perfect for Metrios optical, non-contact measurement machines below:

Key applications perfect for Metrios optical, non-contact measurement systems

Mass Produced Parts

Mass produced parts are a key application for Metrios technology, utilising its speed and multi-part measurement capabilities to enable 100% inspection rates, reducing inspection time to seconds, increasing throughput and unlocking capacity on the shopfloor.

Injection Moulding

Injection moulded components are often delicate and made from sensitive materials which risk being damaged if measured using traditional, contact based technology. Metrios non-contact measurement has revolutionised the inspection of injection moulded parts, delivering accurate component measurements without any physical contact.

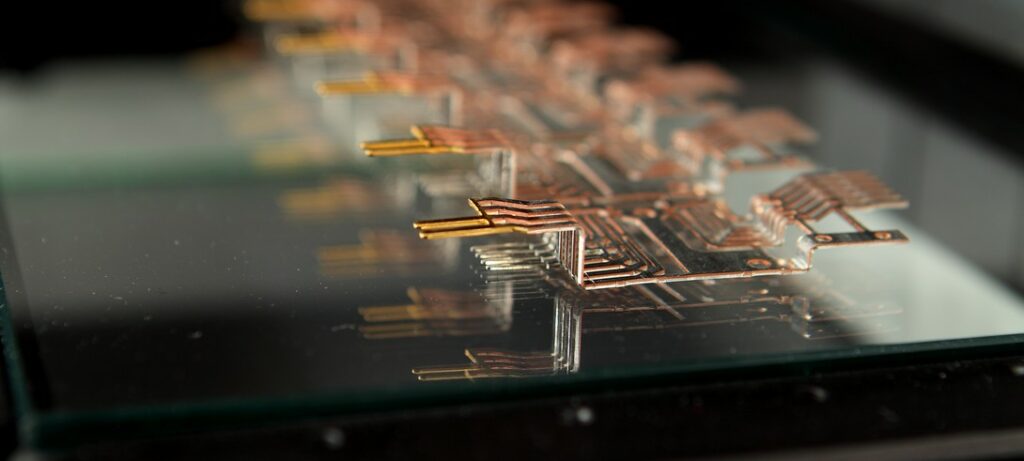

Metal Components

Metrios non-contact measurement technology’s high-speed inspection, microscopic-level precision, and streamlined workflows is ideal for the inspection of metal components in high-volume manufacturing environments. It significantly reduces inspection time whilst ensuring consistent, high-quality results.

Steel Components

For steel component inspection, Metrios’ intuitive and user-friendly software interface allows operators to confidently and efficiently measure parts, regardless of their level of experience or the complexity of the component.

Springs

Metrios non-contact measurement systems’ high-resolution is perfect for measuring springs, precisely capturing critical dimensions including coil diameter, pitch, and free length with unparalleled accuracy to ensure consistent performance and quality control.

Pressings

For pressing applications, Metrios offers valuable insights into force distribution, contact area, and surface topography, utilising non-contact measurement to eliminate part damage, optimise pressing processes, ensure consistent product quality and minimise defects.