In modern manufacturing, shopfloor operators play a critical role in ensuring product quality and production efficiency.

They juggle numerous tasks, from machine operation and material handling to visual inspection and dimensional measurement. With razor-thin margins and ever-tightening deadlines, operators need technology that is simple, fast, easy to use and understand, and above all, reliable.

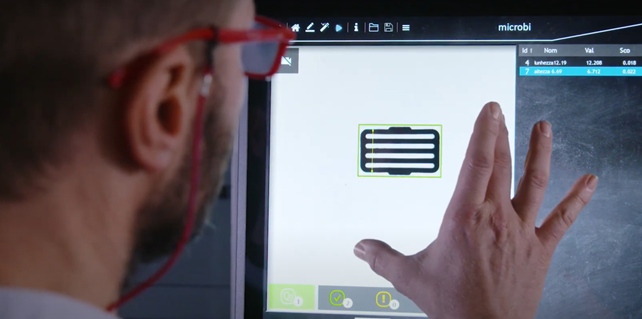

Metrios provides fast and accurate optical measurement systems for measuring multiple parts simultaneously. Its intuitive software and touchscreen interface allows operators to navigate the machine and work smarter, faster, and more efficiently.

Five ways Metrios’ user-friendly technology will simplify shopfloor operator’s workload

1. Repeatability & Standardisation

Working to micron tolerances, Metrios delivers unmatched accuracy and precision to guarantee parts meet even the most stringent specifications, minimising scrap and improving product quality.

2. Multi-Part Measurement

Measuring each component individually is time-consuming for operators. Metrios can measure multiple parts simultaneously, significantly reducing inspection time and increasing shopfloor throughput.

3. Built-in Temperature Compensation

The Metrios is designed for even the harshest shopfloor environments. Its automatic temperature compensation ensures accurate results and eliminates the need for manual adjustments and recalibration, saving operators valuable time and effort.

4. Increased Throughput

The combination of intuitive software, high resolution optics, and multi-part capability enables Metrios to boost throughput by over 100% compared to conventional inspection methods.

5. Intuitive Touchscreen Interface

The Metrios’ simple, intuitive touchscreen technology requires minimal training and enables operators to navigate inspections confidently. Its user-centric design helps operators to streamline workflows, as well as ensure accurate and repeatable measurements.