Who are VICIVISION?

VICIVISION manufacture turned part measuring systems for improved efficiency in production. Recognised as one of the world leaders in optical dimensional inspection, VICIVISION supply machines that serve in a variety of industries from consumer goods to manufacturing; automotive to aerospace and medical to dental.

Where is VICIVISION based?

VICIVISION UK is the UK and Ireland distributor for Italian-based company headquartered in Santarcangelo di Romagna in the province of Rimini, Italy. VICIVISION UK are based in Foston, Derbyshire where they have an Advanced Innovation Centre (AIC) suitable for demonstrations and discussions.

Who will I be talking to when I make contact?

The VICIVISION UK team is an award-winning team selling, supporting and servicing the VICIVISION range of turned part measuring machines in the UK and Ireland. One of our experts will answer your query directly to facilitate your journey with VICIVISION.

No matter your requirements, our team are highly-trained to show how VICIVISION systems can work, bespoke to your business. Whether you’re sure on turned part measuring solutions but don’t know where to turn, you are unsure on its capabilities, or you just want to discover more about it – we work with you to get the answers you need. We can talk through your requirements or arrange a no-obligation demonstration. We work to your schedule, and to your requirements.

How do VICIVISION machines work?

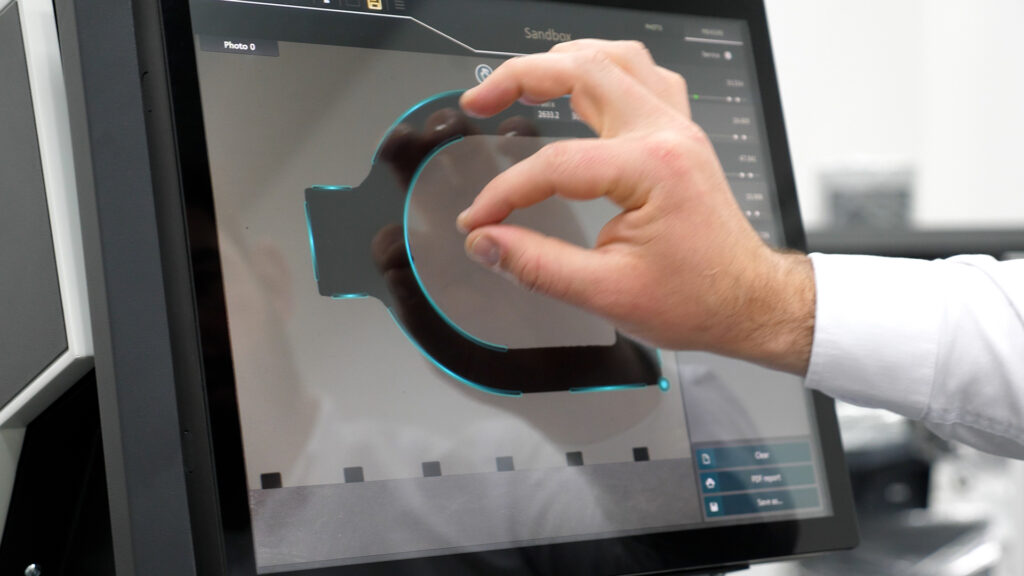

VICIVISION machines work by projecting light onto the shaft or turned part to be measured. The object is simultaneously rotated while a camera placed opposite to the light source captures the smallest details.

Built to withstand production environments, VICIVISION systems are ideal for in-process measuring without having to leave the shop floor.

VICIVISION’s measuring solutions carry out their processes with a simple push of a button. This makes them easy to use despite the numerous rewards they deliver.

What are the main benefits of VICIVISION machines?

360-degree measurement with VICIVISION

Keeping you in control of capacity

What do our customers say?

“What VICIVISION has provided is a reliable, repeatable, accurate measurement solution. We work down to sub 10-micron tolerances on our machine tools and we’re able to reliably repeat those processes using the equipment around us and the technology to verify what we’re doing.

“The VICIVISION machines have become evident as tools for reducing different methods of verification. So previously where we would be utilising micrometers, height gauges and shadowgraphs to check components, now we’re capturing all of that within 30 seconds to a minute on a VICIVISION machine.

“It’s completely revolutionised the way that we go about inspecting parts within Benham.”

Joe Benham – Managing Director at Benham Precision Engineering

“What I’ve seen over the years is you can get so focused on a particular critical dimension or area of a component that sometimes something less critical goes under the radar and ends up being wrong, whereas with VICIVISION you check everything externally and nothing gets missed.

“On a single VICIVISION machine alone, in six months to a year you’ll get your ROI back.”

Nick Street, Managing Director at Trust Precision Engineering