'The Ultimate Shopfloor Gauge'

Modern engineers need to be able to measure parts faster and more accurately than ever before as their products are becoming increasingly complex, and the pace of technological innovation is accelerating. Engineers need to be able to develop and bring new products to the market faster (but without sacrificing their quality) to continue to remain competitive.

Metrios provides fast and accurate optical measurement systems for measuring multiple parts at the same time directly on the shopfloor, increasing efficiency and part quality, vital for engineering companies.

What makes the Metrios the no.1 choice for engineering companies?

SPEED

The Metrios machine is much faster than other measurement systems, measuring features of a component seconds. The advanced technology is able to measure distances, angles, and volumes in real time with a high degree of accuracy.

ADVANCED TECHNOLOGICAL CAPABILITIES

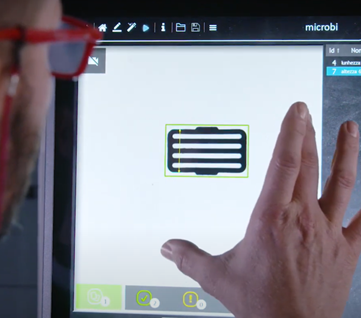

Metrios’ technology allows users to place their component anywhere on the stage and simply draw edges using the touch screen technology for precise measurement in seconds. This automated technology eliminates human errors and provides users with the ability to program complex measurement routines and create custom reports, ensuring accurate and repeatable results.

EASE OF USE

Metrios’ touchscreen technology and user-friendly interface ensures seamless integration with the shopfloor and inspection lab. The intuitive software ensures that anyone could use it without extensive training.

SHOPFLOOR READY

The Metrios’ small footprint is perfect for a busy shopfloor and it is equipped to ensure accurate measurements in the harshest of environments. Its rugged alloy steel construction protects the sensitive parts of the machine and the internal temperature controls ensure it remains stable and continue to produce accurate measurements.

REAL-TIME MEASUREMENT FEEDBACK

The Metrios’ ability to be located on the shopfloor, ensuring manufacturing companies can measure throughout production and receive immediate feedback, allowing any rectifications needed to be made instantly. This guarantees accurate and consistent results, as well as helping to eliminate material, time and financial waste.

DATA MANAGEMENT AND ANALYSIS

The Metrios offers full visibility and traceability for all measurement data, making it easy to track and analyse results over time. Users can access statistics and measurement reports with one click, helping manufacturers to identify trends and make improvements to their production processes.

MULTIPLE COMPONENT MEASURMENT

The Metrios machine uses a combination of multi-camera technology to measure a large number of components simultaneously. This makes it an ideal tool for quality control applications, reducing costs and increasing productivity.