Metrios is a state-of-the-art digital optics measuring machine, which renders precise 2D images of parts with micrometric precision. Designed to optimise the automated environments of Industry 4.0, the need for operator input is minimal, as is the room for human error.

Through its incredibly precise camera technology, Metrios can analyse springs, circuit boards, gear wheels, and a host of other mechanical parts and components, all without the need for contact. Distances, radii, diameters, angles, straightness, roundness, and elements constructed on virtual lines can all be measured within seconds.

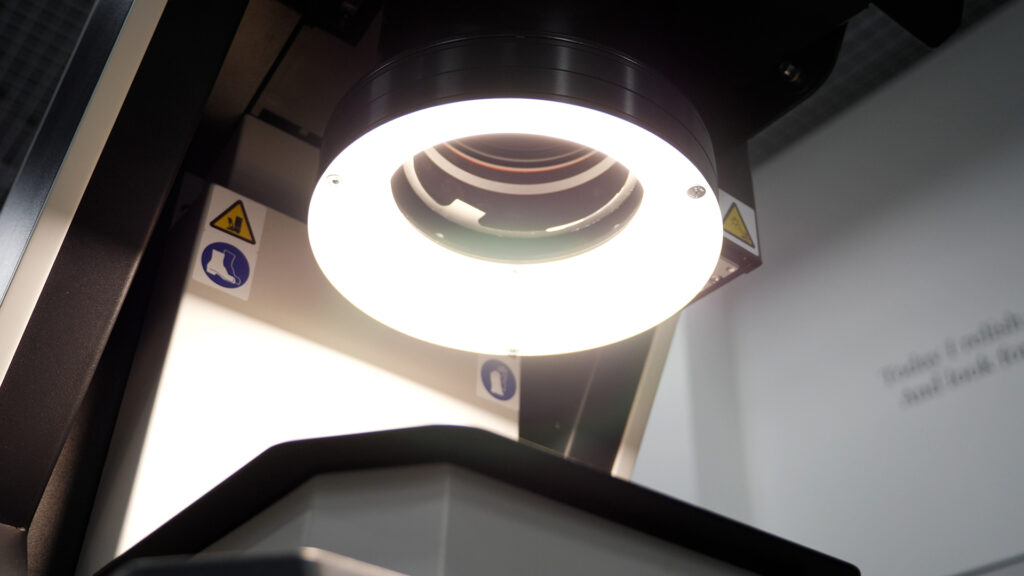

The process is as simple to start as pressing a button. From there, Metrios utilises its 100x optical zoom and three different lighting systems to reveal every feature down to the last, minute detail:

- Telecentric backlighting gives a profile with maximised and repeatable accuracy, eliminating the chances of perspective error.

- A coaxial episcopic illuminator lights up surfaces uniformly, allowing measurement of every detail – even blind holes and markings such as etched writing and embossing.

- An annular illuminator featuring up to 640 LEDs provides customisable lighting fit for fine-tuning. Programmable up to 16 sectors, two rings at different tilt angles can light up a part from any angle to detect bevels and other elements on the surface. Sectors can also be given varying levels of illumination to really outshine ambient light conditions.

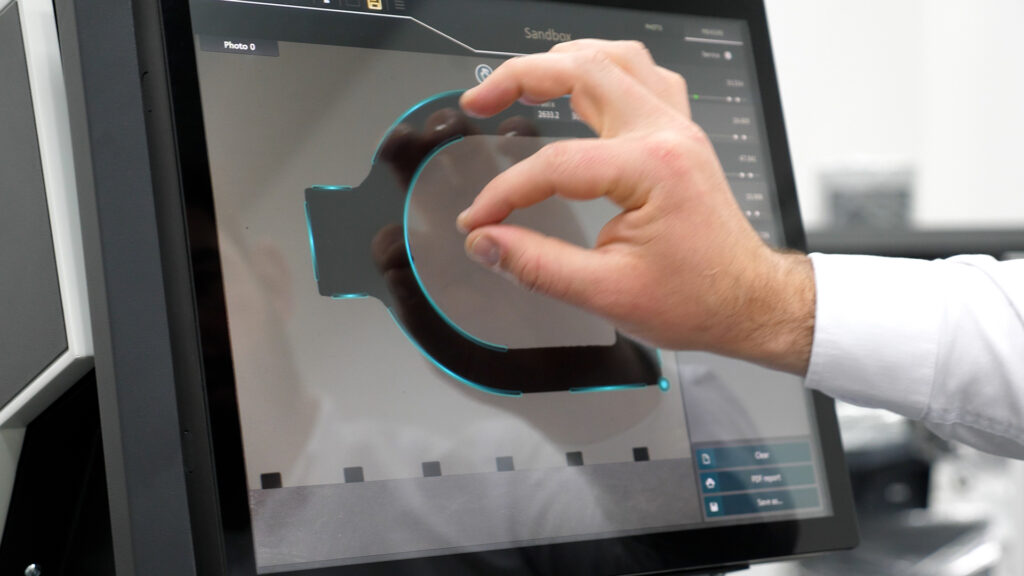

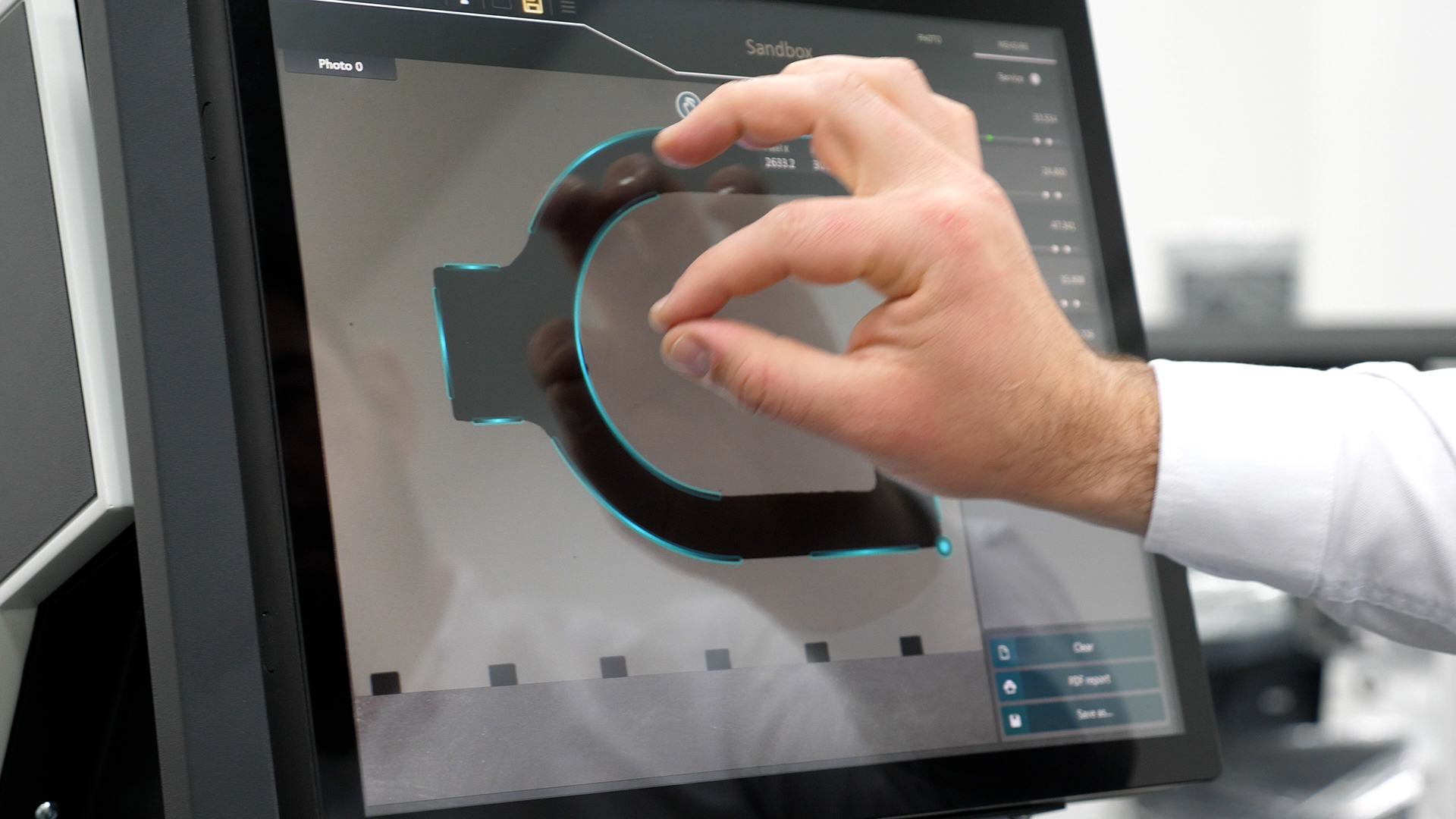

Everything is shown on an intuitive touchscreen display, crafted with easy readability and friendly user experience in mind. Designed to be operated from a typical standing position, with plenty of access space for the operator’s hands and supporting a multitude of hand gestures on the touchscreen, Metrios is powerful as a measuring tool, yet as easy to use as a tablet.

Given the context of shopfloor inspection for which it was made, Metrios’s sophisticated parts are protected within a tough steel alloy structure, with reinforcing ribs to fully bolster it against busy industrial environments. Additionally, since shopfloor environments are not always temperature controlled, Metrios features on-board temperature sensors to ensure that all measurements are taken correctly.

With the optional Metrios in-house software, the machine’s capabilities go ever further. Automatic position detection allows pieces to be quickly placed without the need for accuracy, as the machine will detect and read them accordingly. A histogram display provides an immediate good/reject result for each piece, with a traffic light colour system to signify whether a part is comfortably within tolerance, at the limit of tolerance, or out of tolerance.

All of this takes places whilst the operator sees a live image of the part on-screen, giving the same practical sensation as when using the profile projectors of yesteryear. This provides the operator with immediate control during the process, keeping them and their workflow adaptive, not static; proactive, not reactive.

As Metrios collects data about production, it also notes any emerging trends and displays these clearly for the operator. Monitoring these trends and adjusting parameters accordingly means production can stay in tolerance whilst reducing machine downtime and keeping waste to a minimum, helping productivity go up and stay up.

VICIVISION’s optical measurement solutions have already helped key firms in engineering and industry take their quality control processes to the next level. Find out today how they can do the same for you and your business.