In fast-paced modern manufacturing, producing right-first-time components is essential. VICIVISION UK is a specialist in providing high performance, non-contact measurement systems for turned parts.

VICIVISION UK’s turned part measurement solutions offer three key features that help manufacturers guarantee right-first-time components: shopfloor readiness, offline programming, and frequent inspection. VICIVISION can seamlessly integrates with existing shopfloors, enabling offline inspection programming, and facilitating frequent part inspections, enabling manufacturers to produce high-quality components right from the start.

3 steps that ensure right-first time components with VICIVISION UK

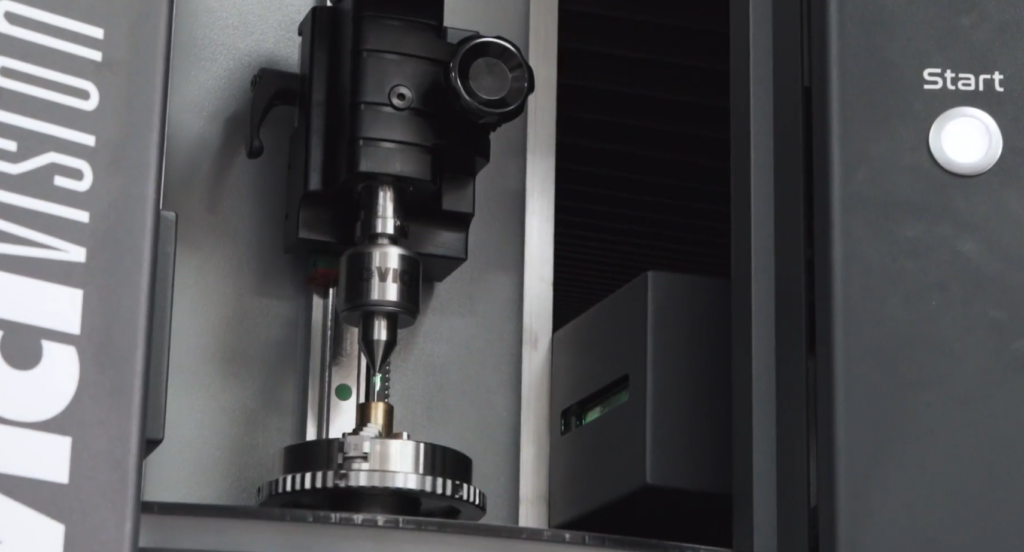

1. Shopfloor Ready

VICIVISION UK turned part measurement machines are shopfloor ready. VICIVISION UK measurement systems have a small footprint, meaning they can be easily integrated with existing shopfloor systems. VICIVISION UK machines are designed to be stable and operate flawlessly within any shopfloor environment. This means that it can live next to a CNC lathe and components can be inspected immediately after coming off the machine. First off components can be instantly measured in seconds to inspect whether there are any discrepancies or amendments that need to be made before production begins. This is vital for ensuring that inspection processes are efficient and effective and produce right-first-time components.

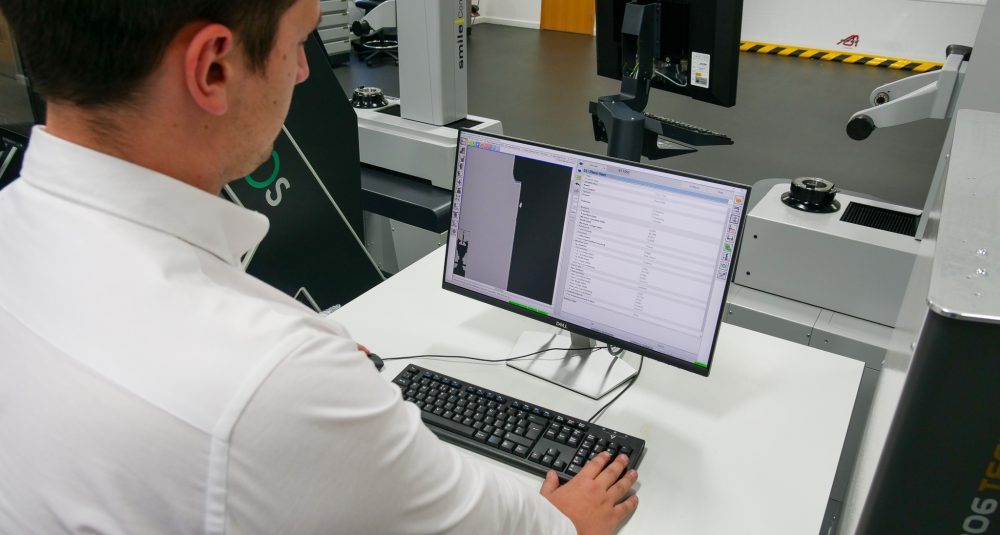

2. Offline Programming

Offline programming saves time and improves efficiency by allowing manufacturers to prepare their inspection processes in advance, rather than having to do so on the shopfloor. VICIVISION turned part measurement machine’s ability to program inspections offline helps to ensure right-first-time components by allowing manufacturers to create inspection programs before production begins. This means that when a first-off component is produced, it can be inspected immediately to identify any discrepancies or amendments that need to be made before full-scale production begins to ensure high-quality, accurate parts are manufactured.

3. Frequent & Ongoing Inspection

The VICIVISION UK turned part measurement machine’s ability to perform more frequent and ongoing inspections helps to ensure right-first-time components, providing greater visibility and quality control over production processes. By inspecting parts more frequently throughout production, manufacturers can identify and correct any defects early on, preventing the production of defective components. It also identifies signs of tool wear that can help manufacturers to prevent tool failures before they occur to ensure only high-quality parts are manufactured. Leading precision engineering and manufacturing company, CNF Precision, invested in a VICIVISION system that has allowed them to perform 100% inspections on their jobs.