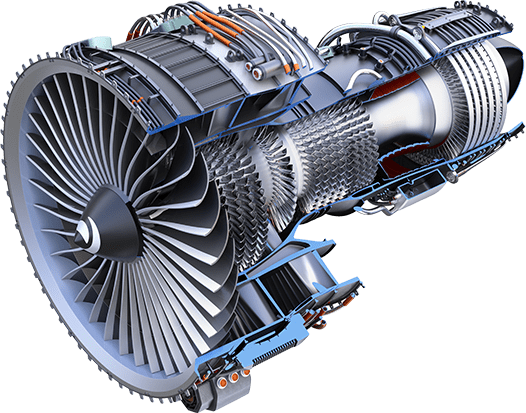

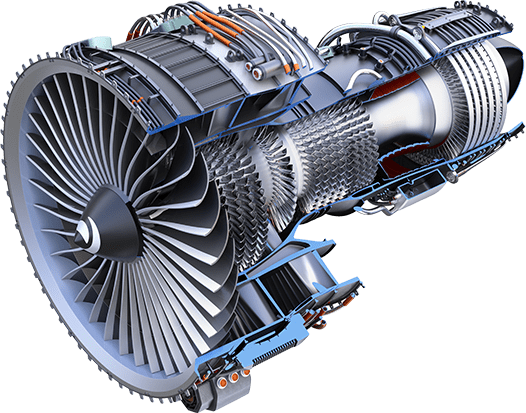

Measurement solutions for turbines

VICIVISION measurement for turbines

Turbines are intricate and highly precise machines with critical dimensional requirements. VICIVISION’s high-resolution optical sensors and advanced imaging algorithms can precisely measure turbine components, such as turbine blades, vanes, and impellers, ensuring they meet stringent specifications.

VICIVISION optical turned part measurement machines utilise advanced optics to capture high-resolution data of your part, allowing for extremely accurate and precise measurements of various parameters.

Quickly scan and capture the entire surface of your part, significantly reducing the inspection time compared to traditional methods and eliminate human errors to improve overall inspection efficiency.

VICIVISION offers non-destructive testing capabilities, allowing manufacturers to inspect and measure parts without causing any damage or alteration to the components, particularly important with high-value or complex parts.

The TECHNO series allows to detect every detail of turbines with or without a stem. The design with direct access to the piece ensures maximum ease of loading and the fairing

completely made of metal offers the right protection from free oil in the environment. The position of the vertical piece ensures ease of loading also for turbines of large size whether you are using tailstock cone rather than chucks or cusps cone negative.

VICIVISION turned part measuring machines are designed to withstand the challenges of everyday measuring. No matter the challenge your team faces, VICIVISION UK experts are on-hand to help you overcome challenging components.

Get in touch with an expert today. Discover the full power of optical measurement to save you time and money with your inspection routines.

Improve the consistency and accuracy of your measurements to create better products. Get in touch today to discover more.

Faraday House,

Woodyard Lane,

Foston,

Derby,

DE65 5BU

Faraday House, Woodyard Lane,

Foston, Derby, DE65 5BU