All-in-one: measure flat & cylindrical parts

A single cycle measurement can be time-consuming which is why Metrios created the RE-LIGHT. This 360-degree inspection system can reduce part measurement to a single cycle, making it faster and quicker than ever. In this post, we’ll take a look at some of the features that make the RE-LIGHT such a valuable addition to your inspection process.

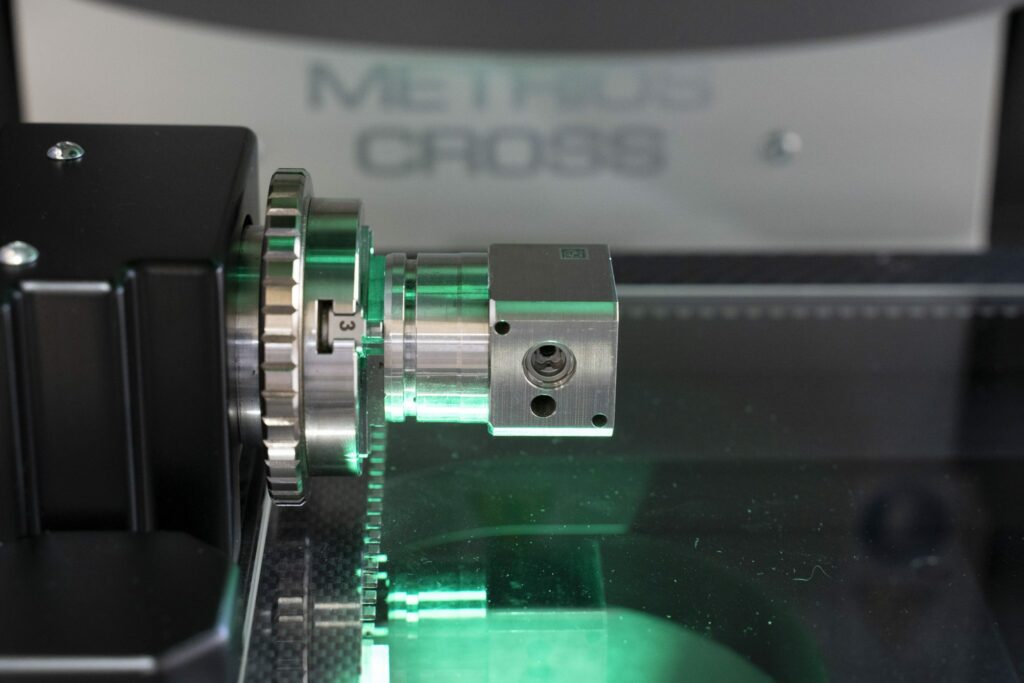

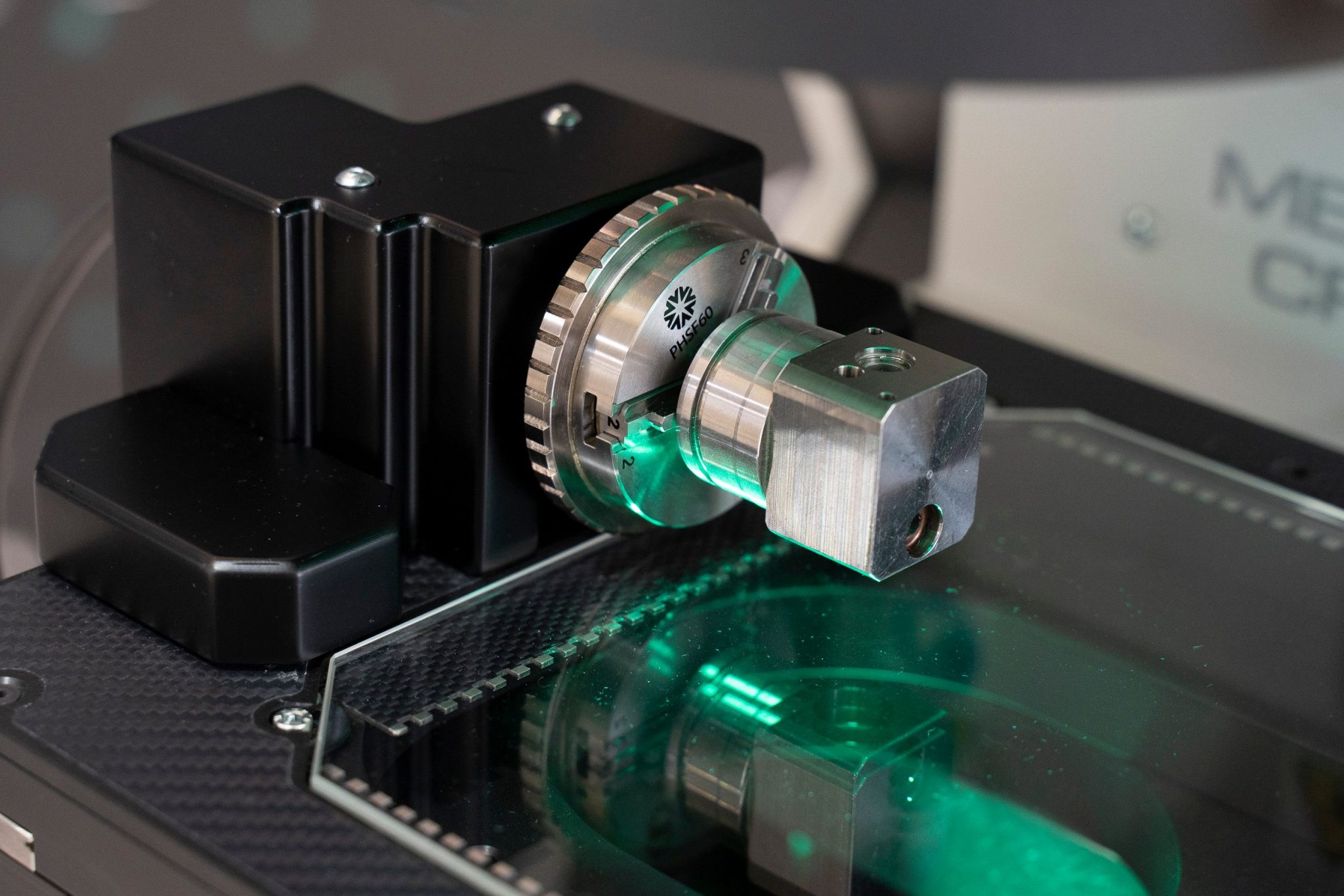

Metrios has a history of proven precision, and the Metrios RE-LIGHT non-contact measuring machine centres around a rotating base that measures in any direction around the part being inspected. In addition, the high-resolution camera enables measuring in tight spaces and all-angle illumination is achieved through three lighting systems providing LED light ring illumination in dark spaces. These features combine to make the RE-LIGHT a powerful and intuitive tool that will help make measurement faster than ever before.

Let’s take a look at these features in more detail:

Measure every side of the part in a single cycle

Automatic rotation, positioning and part orientation makes light-work of measuring all parts from flat to cylindrical. The rotating base on the RE-LIGHT allows you to measure any shape or angle in a single pass.

High-definition, focus & illumination in low-light

The high-definition camera on the RE-LIGHT makes it easy to inspect small parts even in small areas. This makes it the ideal tool for inspecting complex parts that may be hard to reach with traditional measuring methods.

The motorised LED ring light makes the RE-LIGHT perfect for low-light conditions. The light is bright and focused, so it provides high-class illumination without distorting measurements even when changing the angle and providing different angles in the same cycle.

Guided part orientation ideal for complex parts

Not all parts are easy to measure – particularly cylindrical parts like shafts, camshafts, cylinder liners, hydraulic pistons, bearings, bushings, as well as parts with alignment slots, fittings, keyways slots and spanner wrench holes.

The Metrios RE-LIGHT automatically collects the reference point for orientation of the measurement ensuring accurate measurement of diameters, chamfers, keyway slots and more.

Benefits

- Low & reliable cycle time: Get reliable results in a single report while reducing your cycle time and eradicating human error in the positioning phase.

- No doubt your part is level: Make sure your part is always level with the Metrios RE-LIGHT which allows repositioning of parts unable to be placed on glass surface.

- Save money and time: Measure all parts the same every time with automated measurement. The Metrios RE-LIGHT 360-degree rotational inspection system sheds light on every detail – fast and effectively.

- All-inclusive clamping: A universal clamping device means the rotary system comes ready-to-rotate without needing customised fixtures and clamps.

- Touch screen interface: Touch screen interface displays the rotary device measurement in real-time allowing you to monitor the process, as well as select features at the touch of a button.