In today’s fast-paced manufacturing environment, accuracy and efficiency are more important than ever. However, achieving consistent quality in production can be a complex task, particularly when it comes to measurement and inspection.

Metrology challenges can significantly impact productivity, profitability and customer satisfaction. In this article, we’ll explore five common metrology challenges faced by manufacturers and how optical measuring machines offer precise, reliable solutions to keep quality at the forefront of production.

How Optical Measuring Machines Help

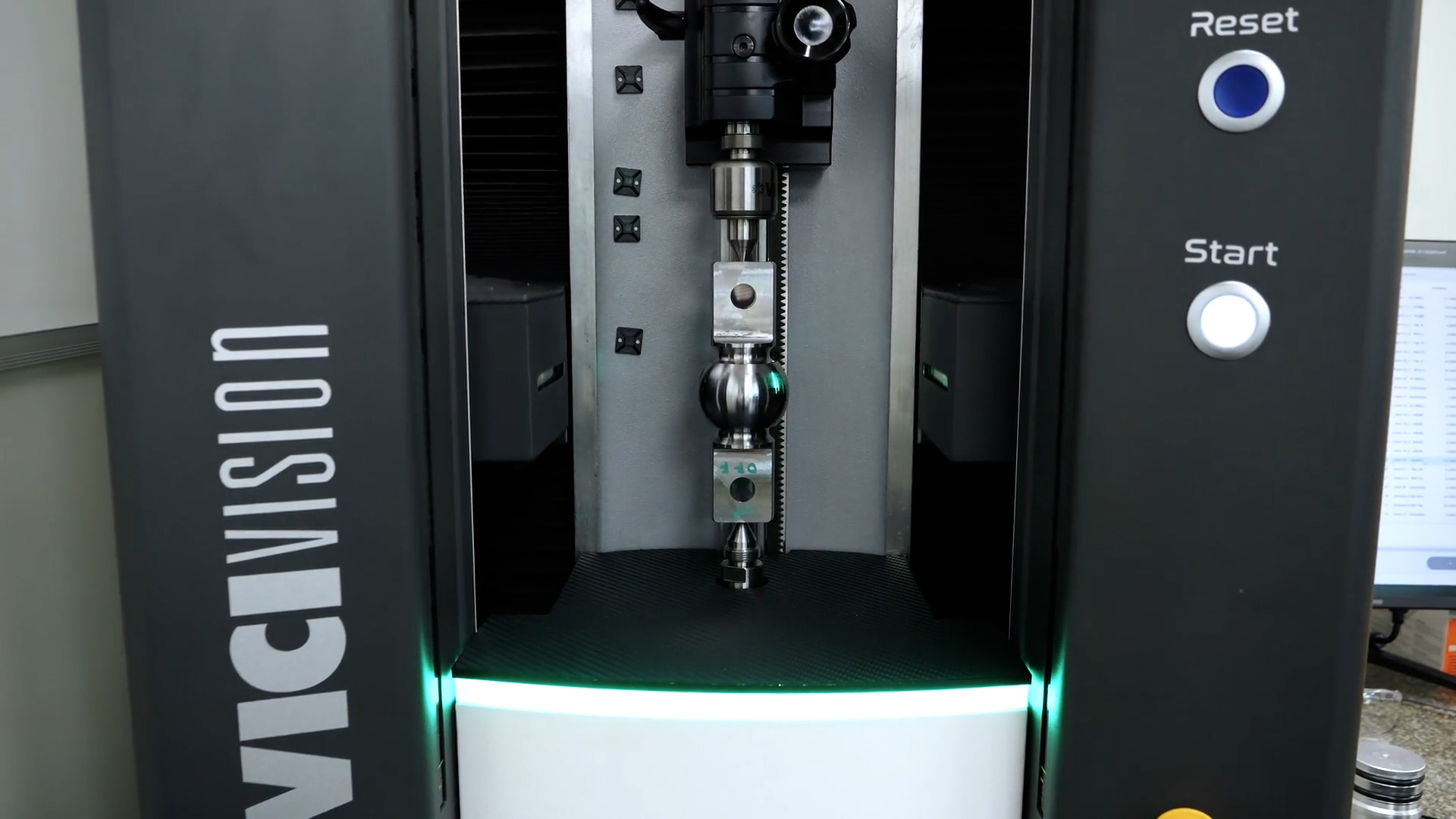

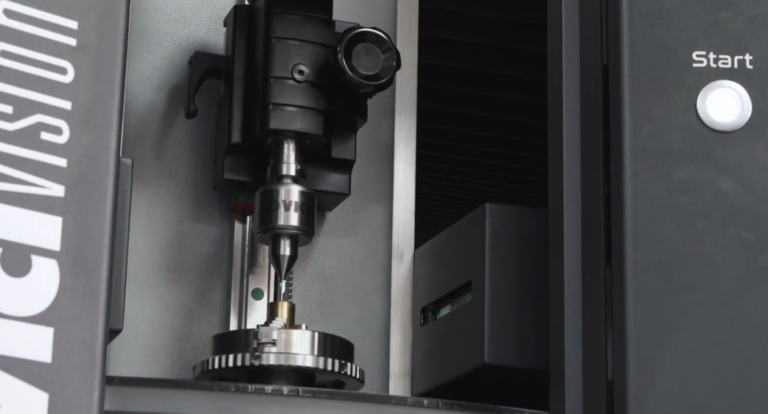

Optical measuring machines use advanced imaging technology and software to capture detailed measurements of components without physical contact. This non-contact approach ensures speed, accuracy and repeatability, all essential in overcoming today’s most pressing metrology challenges.

Challenge 1: Inconsistent Measurements from Manual Inspection

Manual inspection methods, such as using callipers or micrometers, can lead to inconsistencies due to operator error, tool wear or varying techniques. Even experienced inspectors can struggle to produce repeatable results across multiple shifts or teams.

Optical measuring machines, like those from VICIVISION UK, eliminate human error by automating the measurement process. This ensures consistent, repeatable results no matter who operates the machine, and delivers greater confidence in your quality control processes.

Challenge 2: Time-Consuming Quality Checks

Traditional measurement methods are often slow and labour-intensive, which can create bottlenecks in production. When parts need to be removed from the line for inspection, it increases downtime and reduces overall efficiency.

With optical measuring machines, full inspection cycles are significantly faster. Operators can perform rapid, automated measurements directly on the shopfloor, allowing for real-time quality control and increased throughput. The result? Less waiting, more making.

Challenge 3: Difficulty Measuring Complex Geometries

As component designs become more intricate, traditional tools can struggle to capture precise measurements , particularly for turned parts, grooves, threads or small radii. This can lead to inaccurate data and potential non-conformance.

Optical measurement systems are purpose-built to handle complex geometries with ease. Using high-resolution cameras and rotary axes, these machines deliver precise measurements of even the most challenging part features, all without damaging the component.

Explore how VICIVISION UK helps manufacturers master complex metrology tasks with their range of optical measuring machines.

Challenge 4: Lack of Real-Time Process Feedback

When measurement data isn’t available instantly, it becomes difficult to make timely decisions that prevent defects or reduce waste. Without real-time insights, manufacturers risk producing large volumes of out-of-spec parts before identifying an issue.

Optical measuring machines integrate seamlessly into production workflows to provide immediate feedback on part quality. Real-time data enables operators to make on-the-spot adjustments to machining processes, ensuring better control, fewer rejects and lower costs.

Challenge 5: Inefficiencies in Data Collection and Reporting

Inaccurate or incomplete measurement data can compromise reporting, traceability and regulatory compliance. Collecting and managing measurement results manually also increases the chance of data entry errors and slows down reporting.

By using optical measuring machines, manufacturers benefit from automatic data capture and digital reporting capabilities. Integrated software stores all measurements and inspection results, enabling seamless traceability, simplified audits and quick access to performance metrics.

Stay Ahead with Optical Measuring Solutions from VICIVISION UK

Whether you’re struggling with time-consuming inspections, inconsistent measurements or complex part geometries, VICIVISION UK provides powerful solutions to overcome your most pressing metrology challenges.

With a full range of high-performance optical measuring machines, VICIVISION UK supports manufacturers across the UK with technology that drives productivity, accuracy, and growth.

Ready to transform your inspection process? Get in touch with the VICIVISION UK team to discover the right optical measuring solution for your business.