The pinnacle of turned part measurement

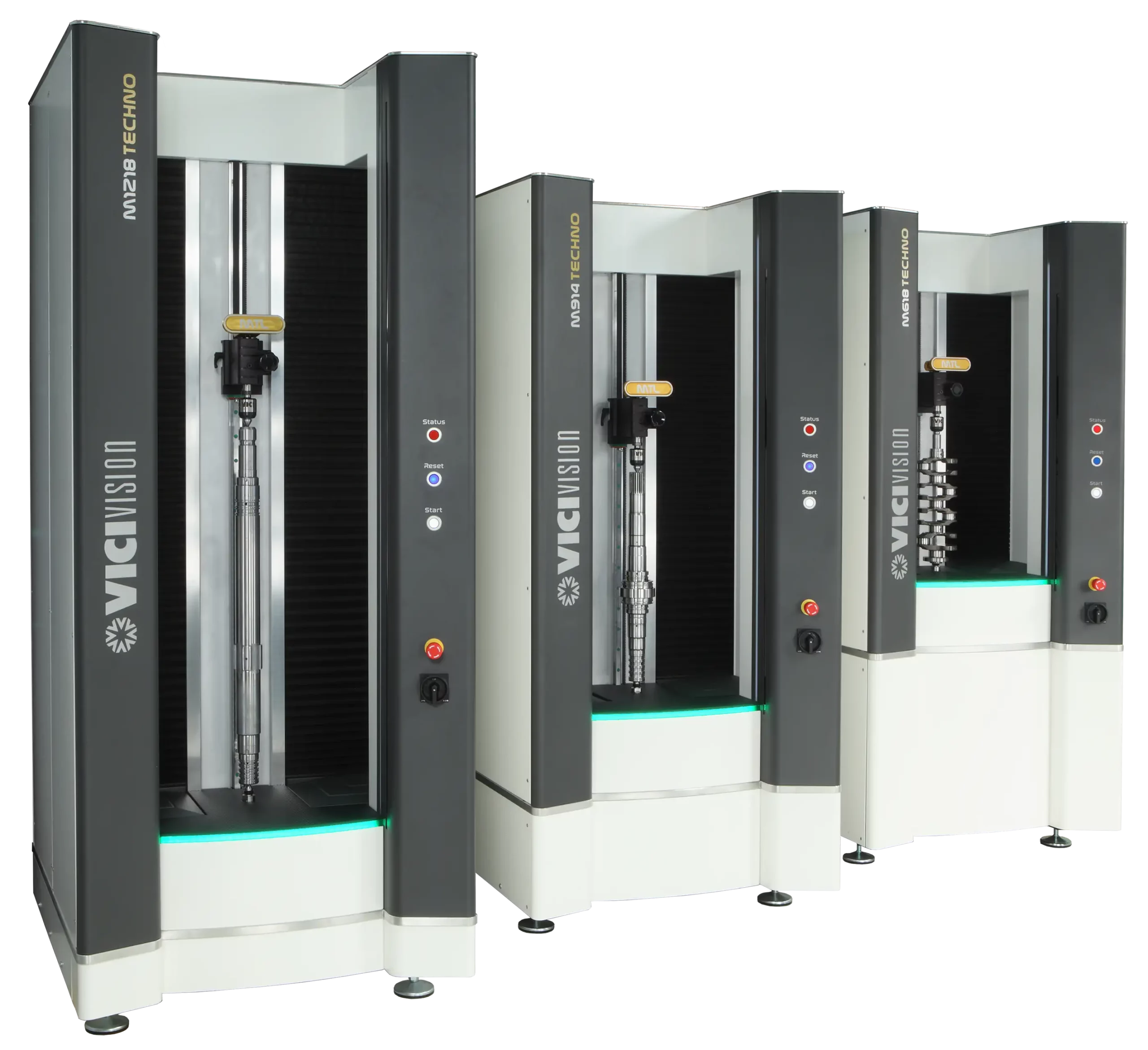

Techno range

Achieve unrivalled accuracy and benchmark reliability in measuring cylindrical parts with the Techno series, which ticks all the boxes for achieving lean manufacturing.

Multiple applications

The Techno range from VICIVISION is designed specifically for measuring turned parts, such as those used in the automotive, aerospace, and medical industries. The range includes different models, such as Techno which offer a variety of measurement capabilities and features.

Greater productivity

The maximum load capacity of the largest machines is 60kg, while high-resolution capabilities mean minute features are captured in detailed images. Thanks to an on-board self-calibrating step-master, each part produced by a CNC lathe can be measured on the shopfloor, leading to greater productivity.

Immediate results. Immediate action.

Making immediate inspection results available next to multiple machining centres, to more than one operator, eliminates bottlenecks and leads to a reduction in downtime as there is no need to leave the production environment, contributing to a significant reduction in rejects and rework.

Which Techno machine is right for you?

M300

Compact inspection

A range of compact, efficient optical measuring machines, designed for small workpieces.

M600

Precise, fast, adaptable

A versatile series of optical measuring systems, tailored for small to medium workpieces.

M900

Inspection excellence

A robust collection of advanced optical measuring solutions for larger, complex workpieces.

M1200

Unrivalled precision

Cutting-edge optical measuring machines designed for large, intricate workpieces

Book your

in-person demo

Book a free demo at our Advanced Innovation Centre where you can see the full scope of VICIVISION technology and how it can transform the way you work.

Download specification sheet

Get the full technical data on the Techno range today. Discover the key technical information including measuring fields, load sizes, accuracy and repeatability.