In the race to stay competitive, modern manufacturers are under pressure to produce more, reduce waste and ensure the highest standards of quality, all at the same time. But balancing speed and precision isn’t easy, especially when relying on manual inspection methods.

That’s where automated measurement solutions come in.

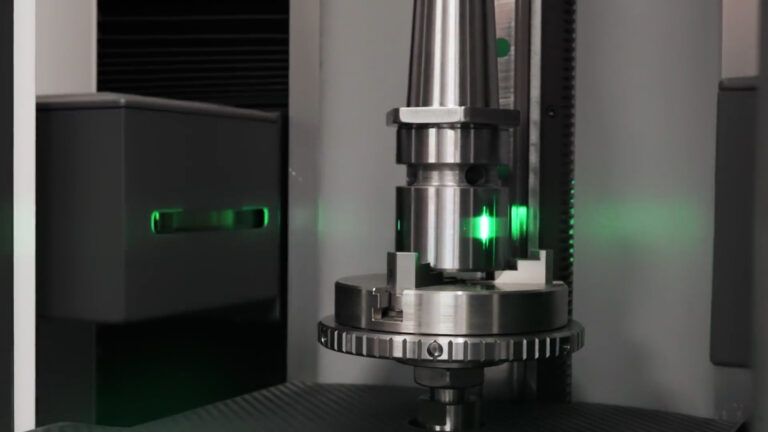

In this article, we explore how technologies like optical measuring machines are transforming inspection processes and helping manufacturers achieve new levels of efficiency in both production and quality control.

The Need for Automation

As demand increases and tolerances tighten, traditional measurement methods often struggle to keep up. Manual inspections can be time-consuming, prone to error and inconsistent, particularly when performed under pressure on busy shopfloors.

Relying on outdated or inefficient quality control methods can lead to bottlenecks, inaccurate measurements or even rejected batches, all of which eat into profits and damage customer trust.

Automated measurement solves these challenges by bringing speed, reliability and intelligence into the heart of the inspection process.

Benefits of Automated Solutions

Adopting automated measurement solutions, such as those offered by VICIVISION UK, delivers immediate and long-term benefits across your production workflow. Here are three key areas where automation increases efficiency:

Speed

One of the most immediate advantages of automation is speed. Optical measuring machines can complete complex inspections in seconds, capturing thousands of data points instantly and eliminating the delays associated with manual checks.

This rapid performance not only increases throughput but also allows for in-process inspection, helping manufacturers catch issues early, reduce rework and maintain momentum on the shopfloor.

Explore the full range of automated optical measuring machines from VICIVISION UK.

Consistency

Human error is one of the most common causes of measurement inconsistency. Different operators, tools or conditions can lead to variable results, making it harder to ensure repeatable quality across multiple shifts or locations.

Automated measurement solutions deliver consistent, repeatable results every time. With no operator influence, every measurement is accurate and aligned to your specification, ensuring reliable data for every component.

This level of consistency supports tighter tolerances, higher quality standards and improved customer satisfaction.

Cost Savings

While automation may seem like a significant upfront investment, it quickly pays for itself. By reducing manual labour, speeding up inspection times and cutting the cost of scrap and rework, manufacturers see measurable returns.

Automated systems also reduce the need for re-inspections and free up skilled operators to focus on value-added tasks rather than routine measurements. Over time, this improves workforce productivity and lowers the overall cost of quality.

Unlock Greater Efficiency with VICIVISION UK

If you’re looking to improve productivity, reduce lead times and enhance the quality of your components, automated measurement solutions offer a powerful way forward.

At VICIVISION UK, we provide cutting-edge optical measuring machines that help manufacturers across the UK transform their inspection processes. Whether you’re working with turned parts, shafts or precision components, our systems are designed to optimise performance on the shopfloor.

Interested in seeing what automation could do for your business? Contact our team to book a demo or speak to a metrology expert.