Shaft measurement systems play a vital role in modern manufacturing and precision engineering. With growing demands for accuracy, speed and repeatability, these systems are essential for ensuring that cylindrical components meet stringent quality requirements.

Whether you’re in the automotive, aerospace or general engineering sector, shaft measurement systems provide an efficient solution for inspecting complex turned parts.

In this blog post, we’ll explore what shaft measurement systems are, delve into their benefits and highlight the wide range of applications they serve across manufacturing and quality control environments.

Benefits

Shaft measurement systems offer a host of advantages to manufacturers looking to improve their inspection processes and achieve higher levels of productivity.

Accuracy

One of the primary benefits of shaft measurement systems is their exceptional accuracy. These systems utilise advanced optical and digital technologies to perform high-resolution, non-contact measurements. This allows for the precise inspection of geometric features such as diameters, lengths, radii, chamfers and grooves on complex components.

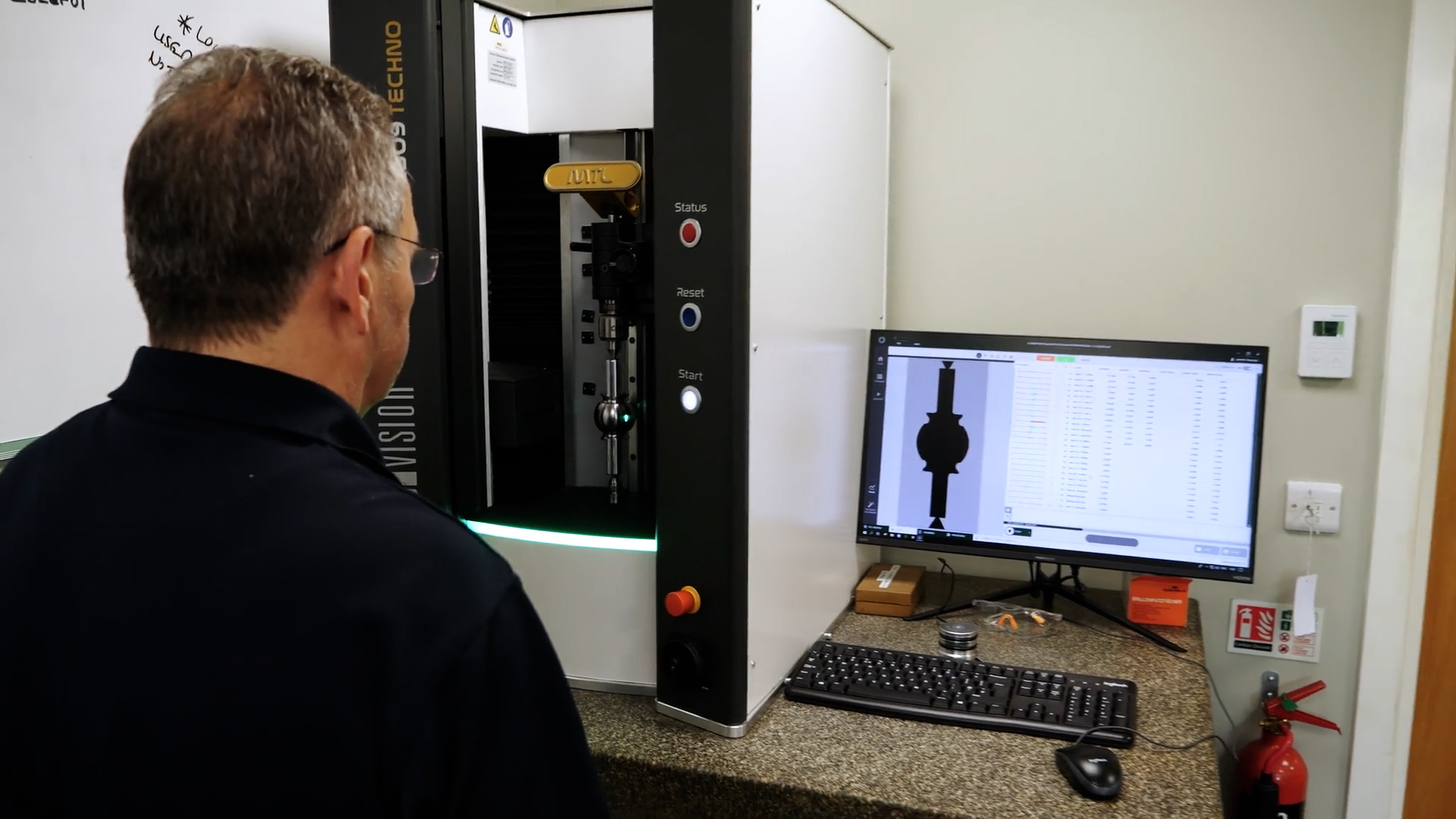

VICIVISION UK’s range of optical measuring machines for turned parts are specifically designed to deliver micron-level accuracy, helping to eliminate human error and reduce costly rework or scrap. By incorporating shaft measurement systems into your production line, you can guarantee parts meet specification with confidence.

Speed

Traditional manual measurement processes can be time-consuming, especially when inspecting multiple features on a part. Shaft measurement systems drastically reduce inspection times by capturing thousands of data points in seconds.

With automated processes and quick-change set-ups, operators can inspect an entire batch of components quickly and reliably. This not only speeds up the quality control process but also reduces downtime and increases throughput – ideal for high-volume production environments.

Flexibility

Modern shaft measurement systems are highly flexible, able to adapt to a wide variety of part geometries and sizes. From small precision shafts to larger cylindrical components, these systems can be configured to suit different manufacturing requirements.

With programmable measurement routines and intuitive interfaces, shaft measurement systems make it easy to switch between different parts or batches, allowing manufacturers to maintain quality standards across a diverse range of components.

Applications

Shaft measurement systems are used across a broad spectrum of industries, wherever cylindrical or rotationally symmetrical parts need to be measured with speed and precision.

Automotive Industry

In the automotive sector, where performance and safety are paramount, shaft measurement systems are used to inspect engine components, gear shafts, camshafts and transmission parts. Ensuring parts meet exacting tolerances is critical for operational efficiency and vehicle reliability.

Aerospace Engineering

Aerospace manufacturers rely on shaft measurement systems for the inspection of turbine shafts, landing gear parts and high-precision aerospace fasteners. In an industry where compliance and traceability are crucial, these systems help guarantee every component is measured to exact specifications.

General Manufacturing

For manufacturers producing components in sectors such as medical, energy or industrial machinery, shaft measurement systems offer a consistent, automated way to maintain quality across complex geometries. They are especially valuable in turning and grinding operations, where high levels of repeatability are essential.

Precision Engineering & Subcontract Machining

Shaft measurement systems are invaluable in subcontract environments where a wide range of part types need to be inspected quickly. Their fast cycle times and easy programming make them ideal for batch inspections and first-off checks, providing detailed results that can be easily shared with customers or regulatory bodies.

Conclusion

Shaft measurement systems are transforming the way manufacturers approach quality control. By offering a powerful combination of accuracy, speed and flexibility, they allow for greater productivity, reduced waste and enhanced customer satisfaction.

At VICIVISION UK, we provide industry-leading solutions for shaft measurement, supporting manufacturers with innovative technology designed to meet the challenges of modern production.

To learn more about how shaft measurement systems can benefit your operations, explore our full range of measurement solutions or get in touch with our expert team.